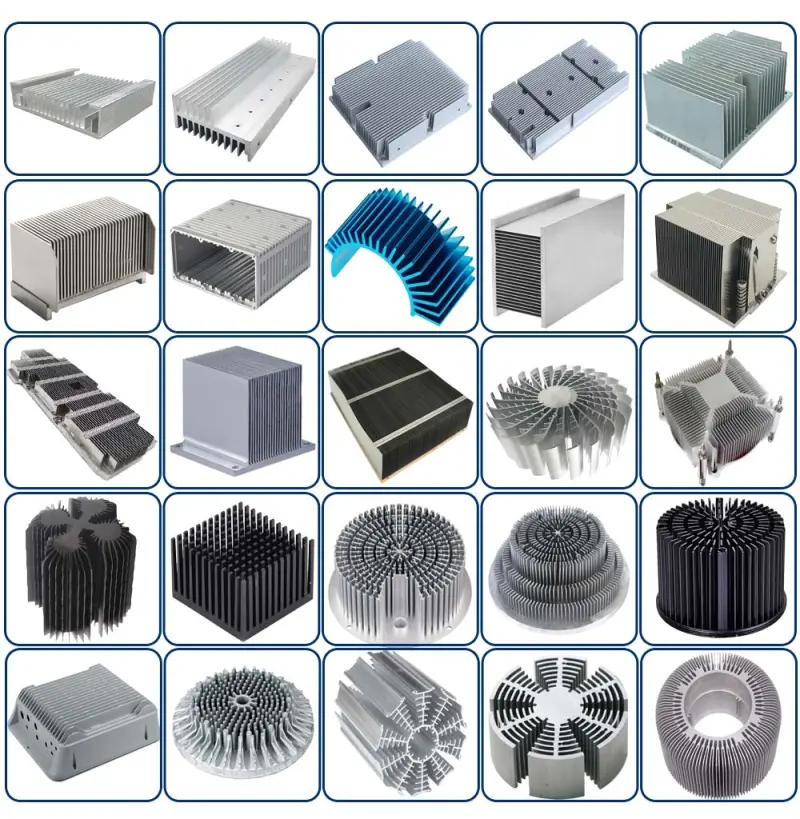

Cheap Aluminium Extrustion Aluminum Heat Sinks

Category:

Detailed

Customized T3-T8 Extrusion Extruded Aluminum Alloy Profiles Round 6061 6082 Small Heatsink Industrial Radiator

Manufacturer Custom CNC 6063 Alloy Profile CPU LED Extruded Aluminum Heat Sink

China factory manufacturer 90mm 70mm 50w led cob large skived fin aluminium cob led light heat sink custom heatsink.

- Product origin: Foshan Guangdong China

- Delivery time: 25-30

-

Extrusion aluminum heat sinks play a crucial role in various applications where efficient heat dissipation is essential.

In the electronics industry, they are commonly used to manage the heat generated by components such as microprocessors, integrated circuits, and power transistors. By providing a large surface area for heat transfer, these heat sinks help to prevent overheating and ensure the reliable operation of electronic devices. The extruded aluminum construction offers excellent thermal conductivity, allowing heat to be conducted away from the heat source and dissipated into the surrounding environment.

For example, in computer systems, extrusion aluminum heat sinks are attached to the central processing unit (CPU) to keep it cool. They help to maintain optimal operating temperatures, which is crucial for the performance and longevity of the computer. Without proper heat dissipation, the CPU could malfunction or even be damaged due to excessive heat.

In power electronics, such as power supplies and motor drives, these heat sinks are used to cool down the power devices. The ability of extrusion aluminum heat sinks to handle high heat fluxes makes them ideal for these applications. They help to reduce the temperature rise and ensure the stability and efficiency of the power electronics.

In the automotive industry, extrusion aluminum heat sinks are employed in various vehicle systems. They are used to cool down engine control units, automotive lighting systems, and other electronic components. The harsh operating conditions in a vehicle require heat sinks that are durable and can withstand vibrations and temperature variations.

In addition to electronics, extrusion aluminum heat sinks are also found in industrial equipment and machinery. They help to cool down motors, generators, and other high-power devices. The customizability of extrusion aluminum allows for the design of heat sinks that are specifically tailored to the requirements of different industrial applications.

Moreover, these heat sinks can be enhanced with additional features such as fins or cooling channels. The fins increase the surface area available for heat transfer, further improving the cooling efficiency. Cooling channels can be incorporated to facilitate the flow of a cooling fluid, such as air or a liquid coolant, for more effective heat removal.

The lightweight nature of aluminum also makes extrusion aluminum heat sinks a preferred choice in applications where weight is a concern. This is especially important in portable devices or aerospace applications where minimizing weight is critical.

Furthermore, the manufacturing process of extrusion aluminum heat sinks offers several advantages. It allows for the production of complex shapes and geometries with high precision. This enables the creation of heat sinks that fit snugly around the heat source and provide optimal cooling performance. The scalability of the extrusion process also makes it suitable for both small-scale and large-scale production runs.

In conclusion, extrusion aluminum heat sinks are essential components in a wide range of industries and applications. Their ability to efficiently dissipate heat helps to ensure the reliable operation and longevity of electronic and other high-power devices. With their thermal conductivity, customizability, and lightweight properties, they continue to play a vital role in maintaining the performance and functionality of modern technologies.

Key words:

Related products

Inquiry

Filling in your telephone and e-mail information will help us get in touch with you in time and solve your problems as soon as possible.